The spinner places an 11-inch blank into a lathe in front of a wooden block called a chuck. A chuck is used to bend the metal to give it a new shape.

My trophy is not silver it is made from a high grade brass. Brass is arguably the best none precious metal as it can be worked almost the same as silver. After the machine is started, the spinner uses a tool to gradually press the metal over the chuck.

The wooden chucks graduate in size until a steel chuck is used to give the ball its final shape. This process is repeated to complete the second half of the ball.

The halves are fitted with four strips to create a lip to lock the ball together. When the ball is in two halves we have access to perfect the finish on the very ends of the ball (the stitching). You cannot do this if your ball is caste in one piece!

Because we can successfully make the ball in two halves and work it almost the same, we have the luxury of using the sheet in the correct gauge (thickness) this then enables us to work in the finer details that are impossible to achieve when using a single mould with a thick uneven finish with no access. As with the real Lombardi our laces are welded into the small dents.

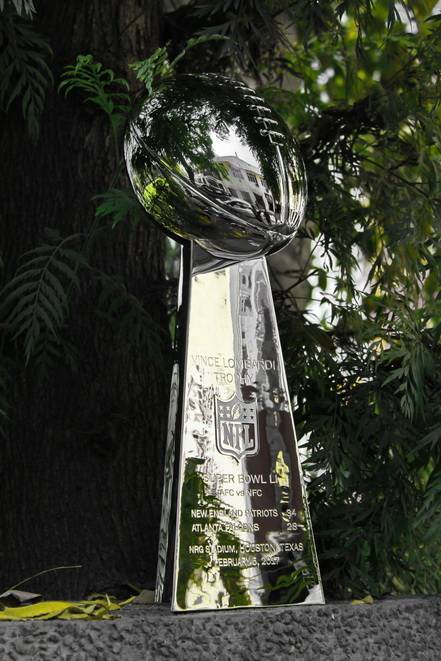

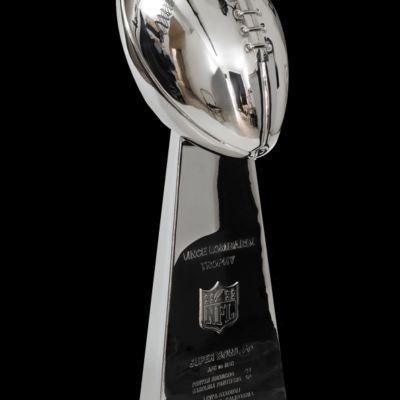

Once all the pieces are polished, the silversmith screws a rod into the ball which is lowered into the base. The ball is then located onto the base and fastened with a nut. This is not a case of engraving a super bowl final onto a finished trophy. Unlike the real Lombardi the engraving/etching is almost the very first step in the process! This is not a solid sterling silver piece; rather the base metal is brass. You cannot engrave over the plating as it will expose the brass. To get the trophy as close as possible to the real sterling silver finish, I must engrave first then plate & polish after.

Using a template as a guide, the sides and bottom of the base are cut from a piece of Brass. The sides are rolled over a cone-shaped block to give it a concave shape. If you look carefully at this picture you will see that the blank base on the table has two holes. People sometime make the mistake of thinking the shield on this trophy is engraved into the base. This is absolutely not the case. The shield is a separate badge that is located into the two holes.

As you can see here with the Denver Broncos coach, Tyke Tolbert’s Lombardi. The finish and the form factor have come together nicely. I designed the art work when the winners trophy was still in the process of engraving after Super Bowl Sunday.